After decades of development, China's industry has entered the ranks of the world's advanced. In such a big situation, China's automobile, communication, medical, clock, mobile phone, computer and other industries have made considerable progress and development. So in such an industry, many have to use one thing, that is, precision parts. Some industries need less precision parts, some need is very much, and each industry needs more than the same parts, the use of course is not the same. Under such a big background, the catalytic precision machining, precision die casting processing industry. In recent years, due to the booming manufacturing in China, the demand for precision parts (zinc alloy die casting) is very much, which makes the rise of precision machining industry. So since there are so many precision machining enterprises rise, it must be more or less there will be some quality problems, today we will talk about how to ensure the production of qualified precision machining parts.

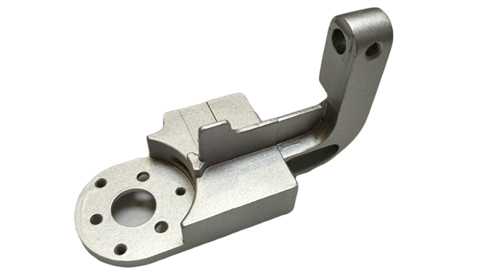

Aluminum Die Casting parts

1, first of all, from the business units to the business, need each other to provide the precision parts drawings, and then according to the image, study and repeated proofing, this project, the company engineers will play a big role, some engineers will see drawings is basically at a glance, while some technicians see drawings have deviation, so the first stepVery important, the first step do not do well, later do more is futile.

2, material selection, there is a saying: good quality, material is very important. Generally speaking, precision machining materials, generally zinc alloy, aluminum alloy, stainless steel and so on. This does not need to grasp the quality, otherwise when the time comes the production, matching to the application of the machine, very easy to damage and wear. Of course, in order to reduce costs, some companies choose materials with low prices, so that they can make money, but later problems will be very big. The other is used when processing to cutting oil, and cutting fluid, the general quality is not much.

3, processing equipment, this link is mainly the purchase of CNC processing equipment, generally speaking, imported equipment processing parts will be less deviation, scrap rate is low, in addition to high productivity. Generally speaking, the equipment imported from Europe, America and Japan is a good choice.

4, of course, no matter how good the equipment, and no matter how good the material also need excellent operators to operate. This piece of course is a year of processing precision parts of the staff to operate of course the best.

5. Finally, the quality inspection personnel. After each part is produced, the quality inspection personnel must check and pass the test in person before it is completely passed. Of course, we also need to pay attention to transportation. After all, some parts of materials are too soft, and if they are pressed too much, they are easy to be damaged. Therefore, we also need to pay attention to this part.

Basically the above five points have been done, so the production of qualified precision parts will not have any problems.